FOR THE TECHNICAL CERAMICS INDUSTRY

MATURE REFRACTORY SOLUTIONS

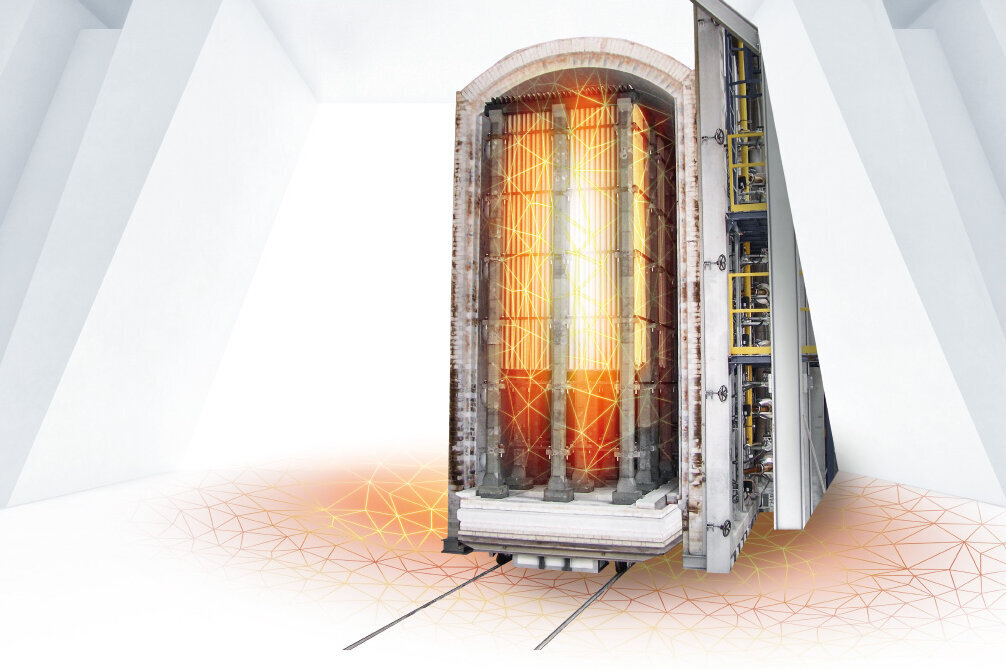

A solidly built ceramics furnace lining is characterized by professional material selection, solid construction, high-quality lining and efficient project management.

Your benefits:

• Expert knowledge and highest refractory quality

• Full-range supplier for the technical ceramics industry

• Comprehensive consulting expertise and worldwide project management for industrial furnace projects

CONSULTING

With expertise and many years of real-world experience, our project managers ensure the execution and coordination of industry furnace projects all over the world. Thus, RATH customers can count on a reliable partner for refractory systems with a comprehensive service portfolio.

ENGINEERING

The basis of every lining concept is the heat transfer, which will determine the optimum wall construction. Here, extensive knowledge of thermal and corrosive loads is essential. To this end, we use modern heat transfer calculation programs and software systems for the calculation of thermodynamic equilibria and phase diagrams.

Reduce energy consumption and costs?

That's where RATH ECOREF® comes in. Using this analysis and concept approach, our engineering experts determine the best refractory lining for any given application – based on the corresponding technological, ecological and business objectives and depending on numerous distinct process and plant parameters. The result of the analysis: concrete savings potentials, defined in kilowatt hours. Find out more here.

MATERIAL DELIVERY

RATH materials are made to order for customers and delivered directly to the construction site by experienced shipping companies according to agreement. No matter where in the world the construction site is, our logistics experts ensure reliable and punctual delivery.

ASSEMBLY

Refractory linings for ceramic furnaces require expert installation during pre-assembly or on site, respectively. Our highly trained assembly staff ensure reliable installation and attach particular importance to high safety standards.

MAINTENANCE AND REPAIR

We monitor the performance of refractory linings and provide the necessary maintenance to ensure safe and reliable operation of the equipment. We also offer ongoing and predictive maintenance and repair.

INNOVATION

With decades of experience in developing and manufacturing high-temperature ceramic fiber, we continually push the boundaries to deliver innovative, high-performance solutions for industrial applications.

Our latest breakthrough is the launch of ALTRA FLEX®, a new oxide ceramic continuous fiber available in three grades. This new development enhances our comprehensive portfolio of future-proof solutions and makes us the first European manufacturer to offer tailored products to composite manufacturers as well as producers and processors of temperature-resistant fabrics.

Learn more here.

In a nutshell

DownloadsSuccess Story

Your perfect solution

APPLICATIONSSOLVING COMPLEX REQUIREMENTS IS OUR SPECIALTY

We match the refractory lining to the furnace design. Customized planning and production make this possible. Each part is pre-engineered in the CAD system and checked for precise fit, so everything runs smoothly on the construction site.

This is how RATH COVERS THE COMPLETE RANGE OF CERAMICS FURNACE SYSTEMS.

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/8/2/csm_RATH-Header-Ceramics-2000x600px_2__a88d0132b0.jpg)