REFRACTORY COMPETENCE FOR SPECIAL FURNACES

Feuerfestkompetenz für SpezialöfenTOP QUALITY THANKS TO IN-HOUSE PRODUCTION

RATH produces top-quality refractory materials and components for thermal insulation in Europe and the USA. The RATH range comprises all refractory materials for insulation and heat storage in plants for industrial high-temperature processes.

- Unshaped refractory products

- Pre-cast blocks

- Dense bricks

- Lightweight refractory bricks

- High-temperature insulation wool

- Vacuum-formed shapes from high-temperature wool

VACUUM-FORMED SHAPES FOR SPECIAL FURNACE CONSTRUCTION UP TO 1800 °C

The high-temperature wools required for the production of vacuum-formed shapes are produced by RATH in-house in Germany (Mönchengladbach).

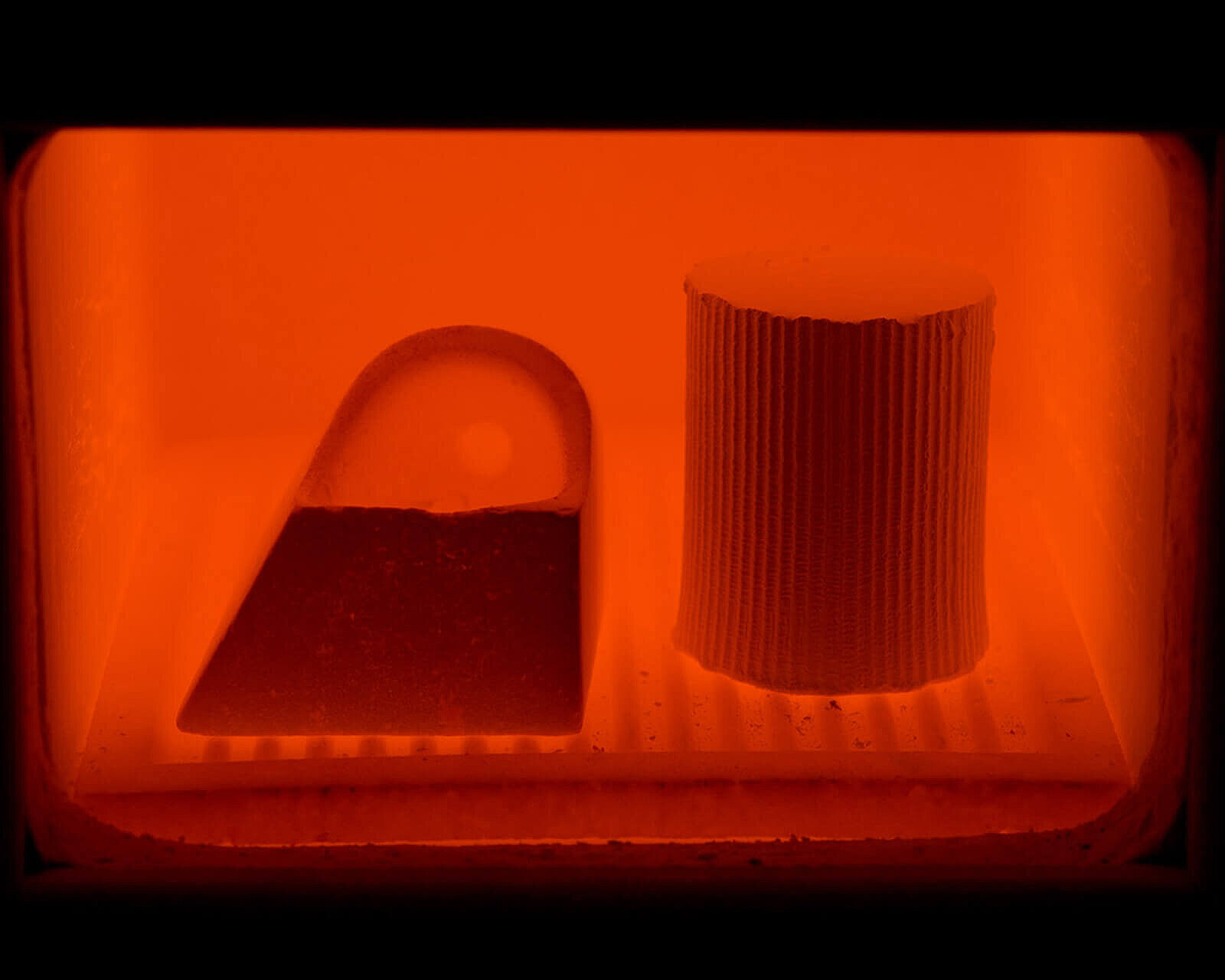

Vacuum-formed shapes are made from synthetically produced high-temperature wool, ALTRA – polycrystalline wool (PCW), ALSITRA – aluminum silicate wool (ASW) or CALSITRA – alkaline earth silicate wool (AES) in a special vacuum suction process and then brought into the required shape by mechanical processing such as CNC milling. This results in high-precision moldings with low tolerances that conform exactly to the customer’s specifications in terms of geometry and quality.

ANY GEOMETRY AND REQUIREMENT IS FEASIBLE.

Refractory linings by RATH can be used to produce any types and shapes of furnaces, without restriction. The lining is either manufactured according to your specifications or designed by our engineering department based on the geometrical, thermal and atmospheric requirements.

Vacuum-formed shapes can be used in neutral and oxidizing as well as reducing furnace atmospheres. The raw materials used and the manufacturing process ensure very good thermal insulation properties and excellent thermal shock resistance.

Typical industries using RATH vacuum-formed shapes are:

- Food industry

- Chemical industry

- Medical engineering

- Dental technology

- Analytical labs

- Electronics industry

- Manufacturing

YOU ALWAYS HAVE THE PROCESS TEMPERATURE UNDER CONTROL

Refractory linings by RATH are used in a wide variety of industries and applications. Low thermal conductivity and high thermal shock resistance are ideal for very short heating cycles.

The quality and design of vacuum-formed shapes depends on the operating conditions. RATH offers the right product for all applications up to 1800 °C.

Typical applications for RATH vacuum-formed shapes are:

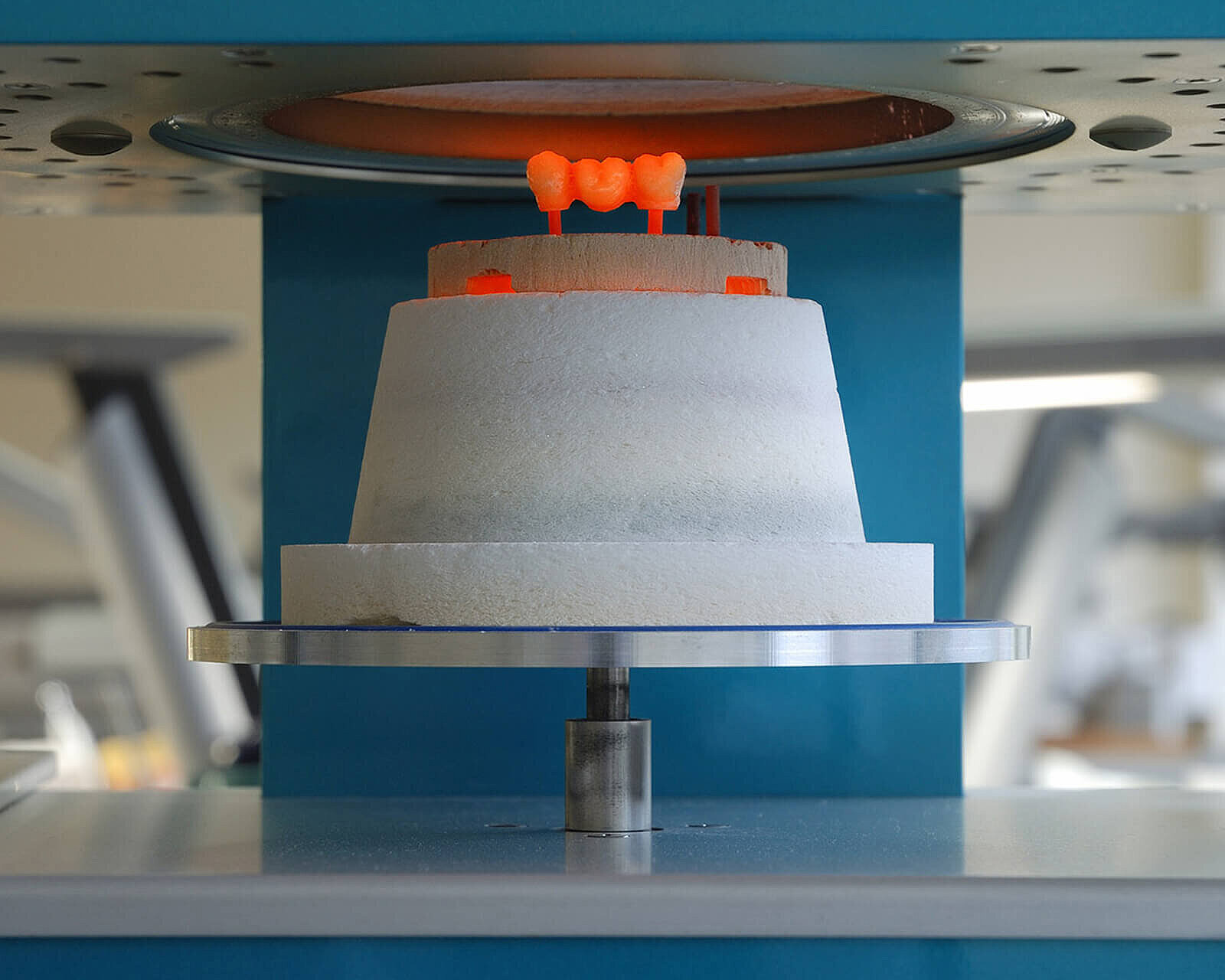

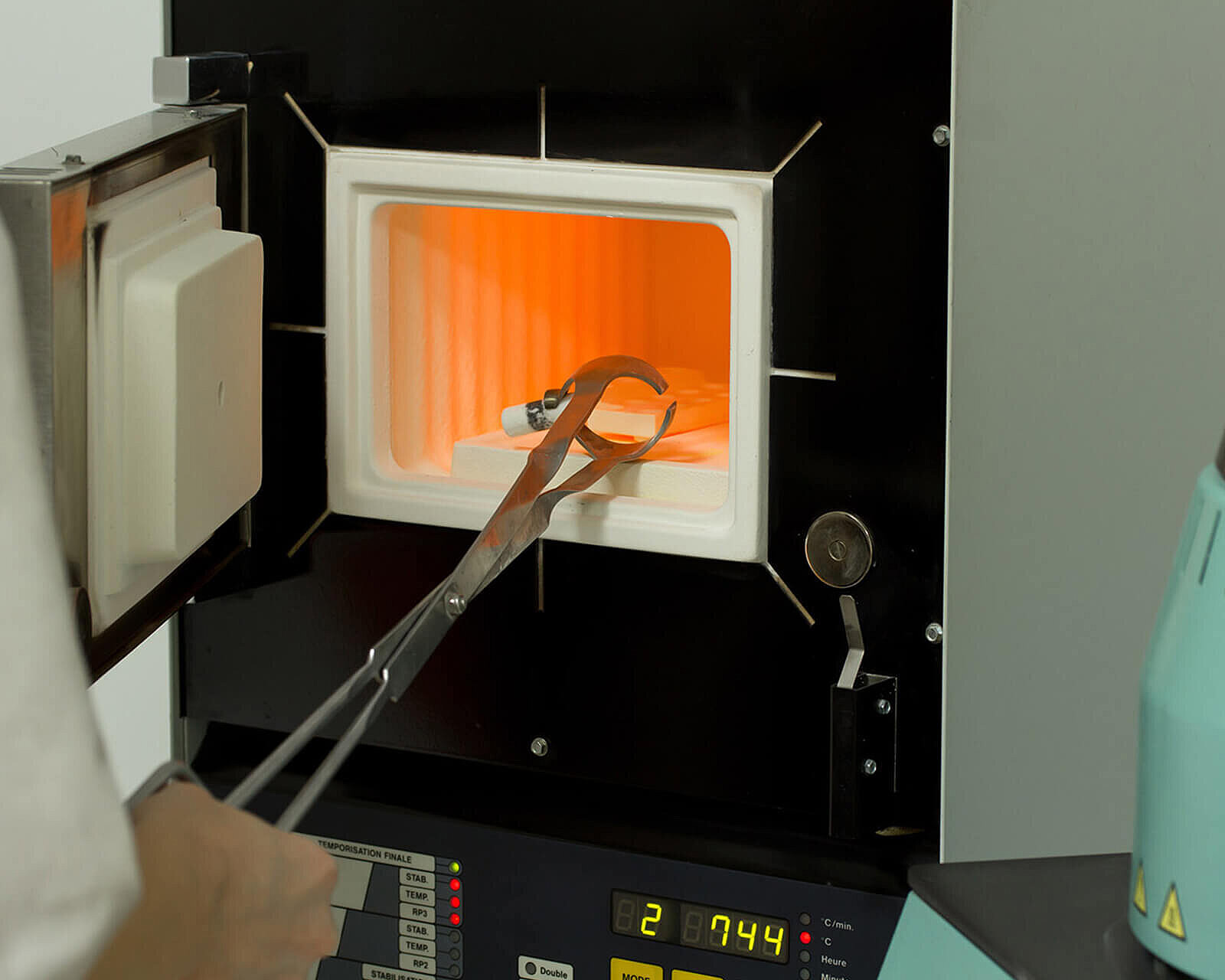

- Dental furnaces

- Gas chromatography devices

- Laboratory furnaces

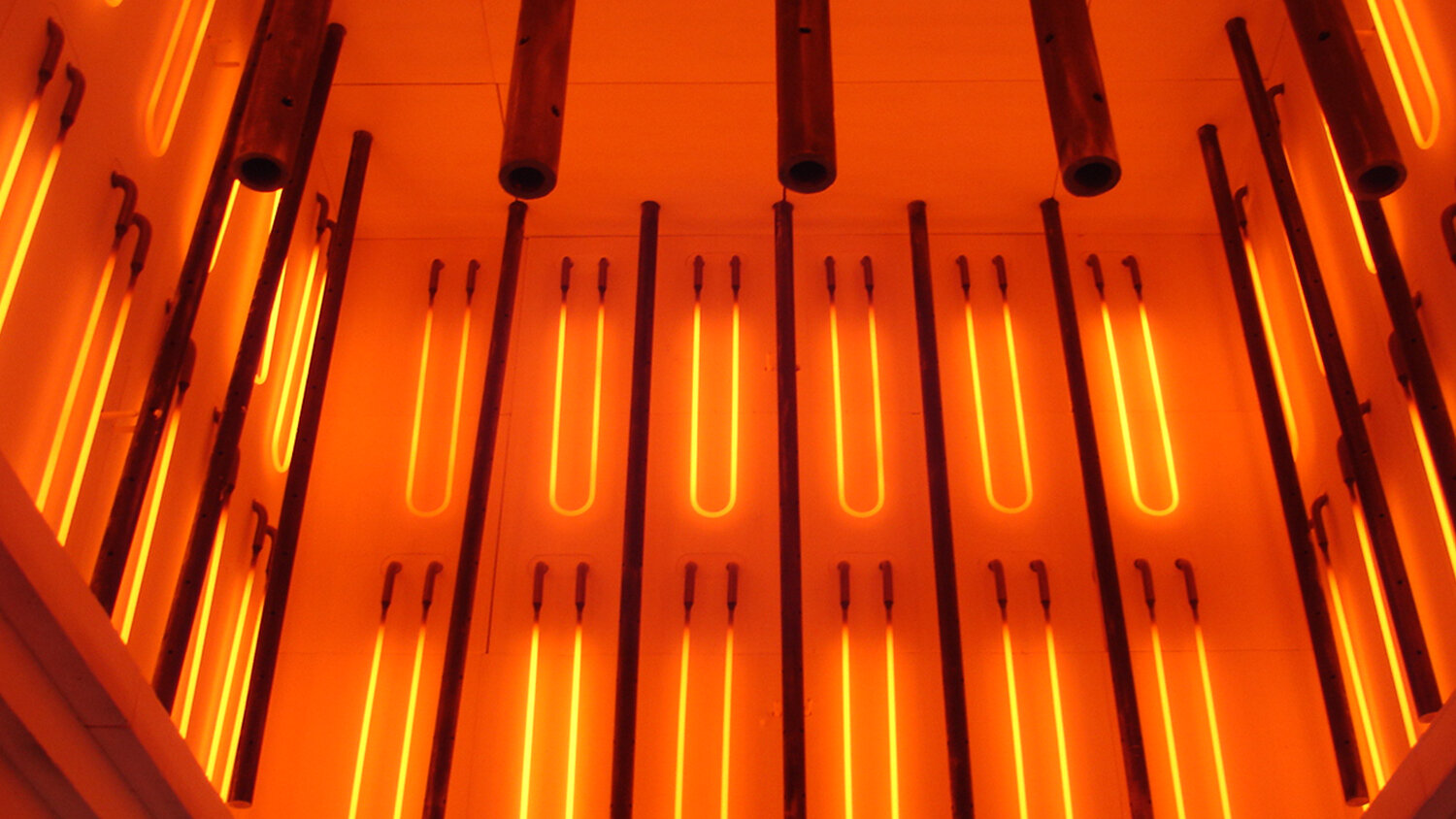

- Continuous furnaces

- Preheating furnaces

- Soldering furnaces

- Sintering furnaces

- Annealing furnaces

- Induction furnaces

- Melting and holding furnaces

The comprehensive RATH range

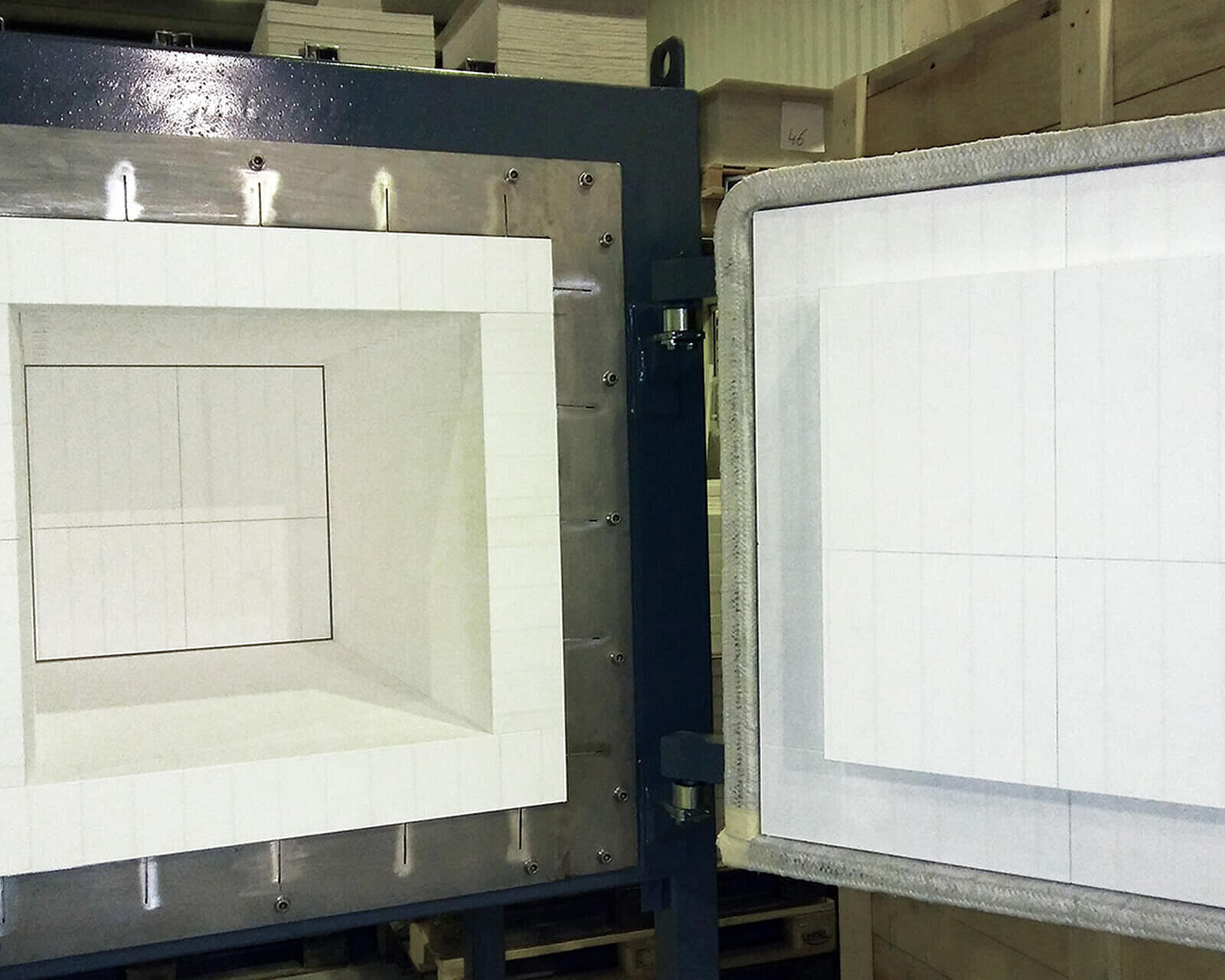

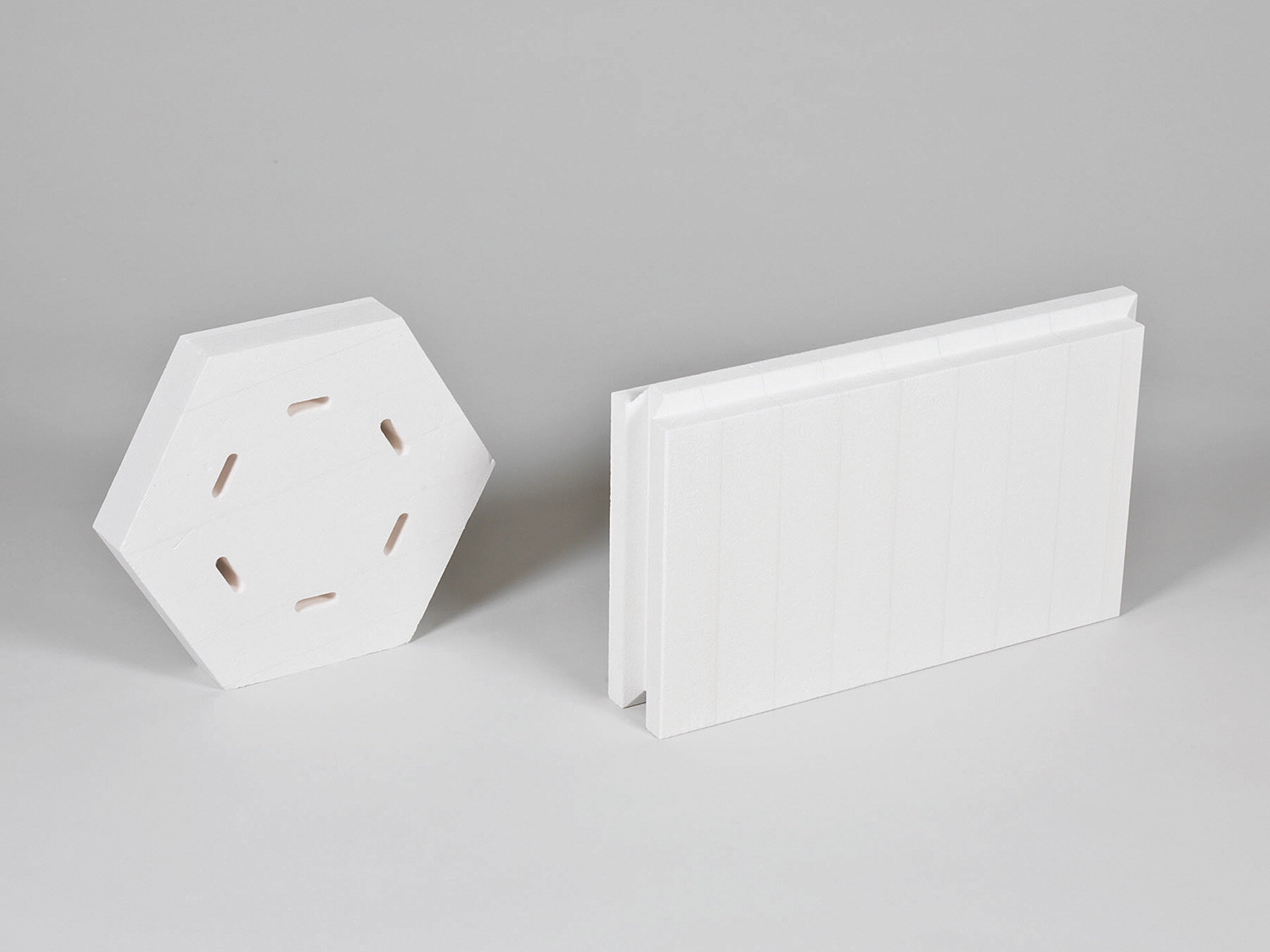

Panels

RATH VFT panels insulate electrically heated and gas-heated industrial and laboratory furnaces at application temperature of up to 1800°C.

Taking into account the operating conditions, products made from appropriate raw materials are used here.

EVAC® EVS up to 1000°C ‒ Kerform® KVS up to 1350°C ‒ Ultiform® UVS up to 1400°C ‒ Altraform® KVS up to 1800°C

MOLDED PARTS

RATH manufactures vacuum-formed shapes for electrically operated and gas-operated high-temperature furnaces according to the customers’ requirements. Due to the possibilities in our plants in Germany, Austria and the USA, we produce moldings in the required qualities and the most diverse geometries and designs, from the smallest to large series.

MATS / MODULES

Mats made of high-temperature wool – CALSITRA® MAT, ALSITRA® MAT and ALTRA® MAT – are a flexible alternative to moldings made of high-temperature wool. They are free of organic components. Their strength is due to a needling process. The mats are available in various thicknesses and gross densities.

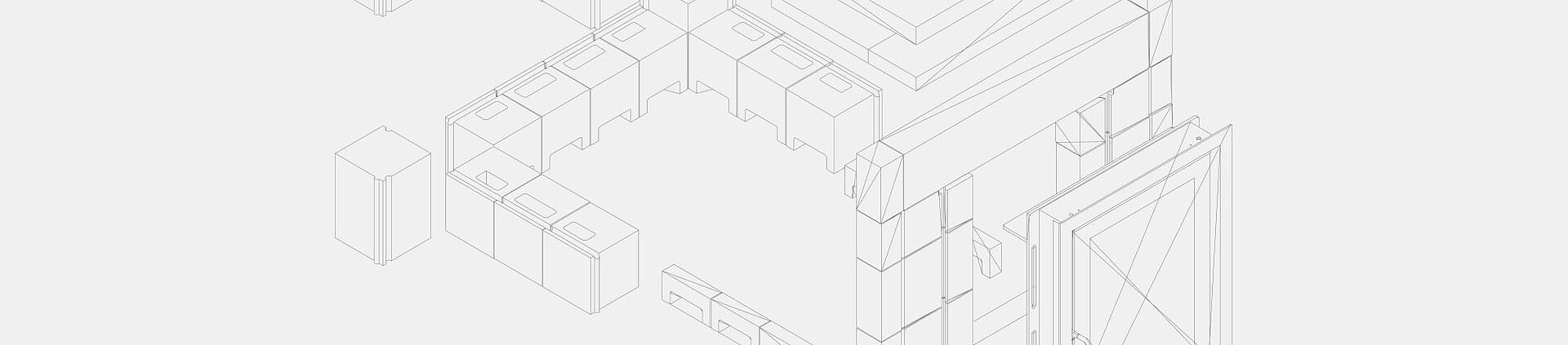

ACS® – THE ALTRA COMPOSITE SYSTEM

ACS® is a specifically developed lining system for the insulation of laboratory and industrial furnaces up to 1800 °C. It consists of freely movable ceiling segments plus tongue and groove elements for the lateral walls. Prefabricated system elements enable quick lining of high temperature furnaces.

ADHESIVE

KERATHIN is the high-temperature adhesive for vacuum-formed shapes and ceramic elements up to 1800 °C. The kneadable ceramic one-component adhesive ensures easy processing and durable adhesive strength.