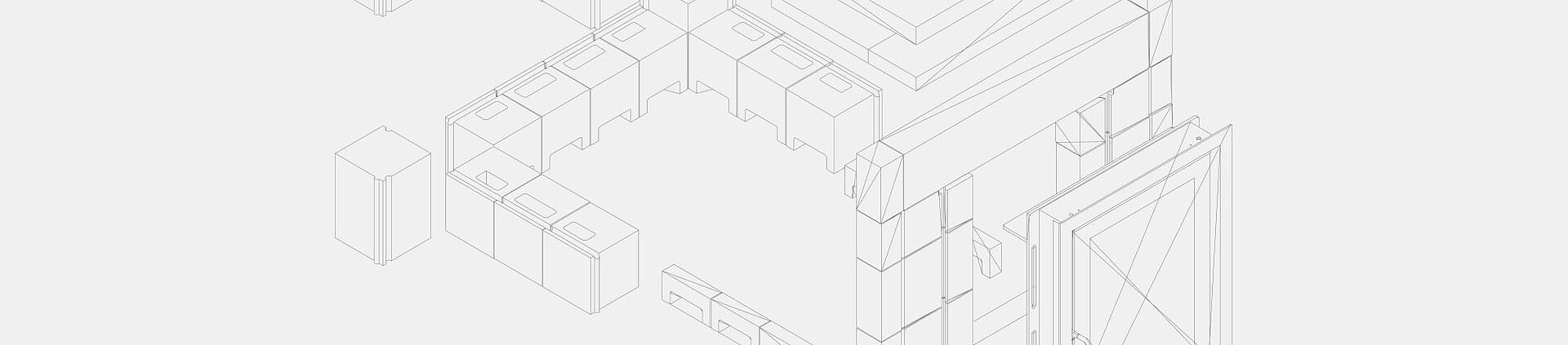

Monolithics

MONOLITHICS (UP TO 1800℃)Rath’s refractory castables offer a wide range of materials with the highest technical standards. Depending on the application, the concretes can withstand up to 1800°C

- Melt-repellent

- CO-resistant

- High chemical resistance

- High structural density

- High strength

- High abrasion resistance

- Volume-stable

- High thermal shock resistance

- Various processing possibilities

Typical applications

Whether dense and insulating castables, low-cement and cement-free castables, vibration concretes and self-flowing concretes, gunning castables, plastic castables, mortars and adhesives or fiber foams and coatings:

For any application, optimum durability can be achieved by a suitable combination of raw materials.

RATH’s concretes and castables feature easy and reliable processability. Low spray loss with gunning castables and maximum adhesive properties are just some of the quality features.

- Production of refractory concrete molded parts

- Shuttle kiln and furnace walls

- Waste incinerators

- Solid fuel fired burners

- Glass production

- Aluminum production

Our brands

Diversity makes the difference- Carath® D dense concretes

- Porrathin® mortars and adhesives for lightweight insulating bricks

- Carathplast® plastic castables

- Carathin® mortars for dense bricks

- Carath® FL insulating concretes

- Carath® NC cement-free concretes

- Carath® ULC ultra low-cement concretes

- Carath® LC low-cement concretes

- Kerathin® K - adhesives for materials made of high-temperature wool