Since February 2022, two furnaces, in which silicon carbide plates and bricks for the lining of domestic waste incinerators are produced in a nitrogen atmosphere, have been electrically operated at the RATH plant in Krummnußbaum (Lower Austria). Only thermal post-combustion is still gas-powered. In the electrically-powered kilns, CO2 emissions have been reduced by around 70% compared to using gas-powered kilns. For SIC production, this means a CO2 reduction of approx. 1.9 tons per ton of fuel.

By operating these two furnaces electrically, RATH is a pioneer in the industry when it comes to silicon carbide production in a nitrogen atmosphere.

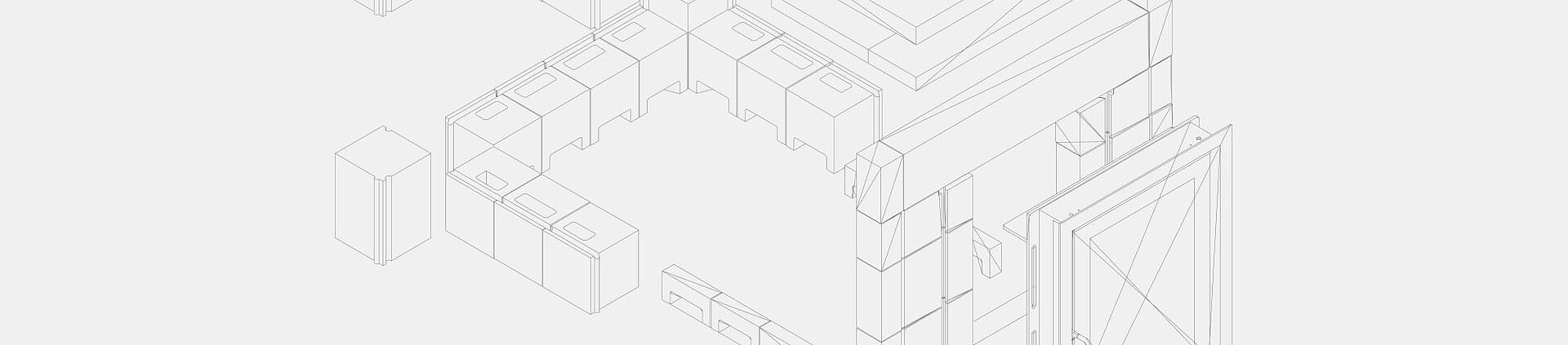

By changing the heat treatment process from gas to electricity, the existing material and the geometry of the firing boxes were adapted and integrated into the firing chamber. To enable the products inside the boxes to be exposed to a nitrogen atmosphere, the firing boxes must be subjected to high temperatures. The aforementioned changes allow for shorter heating and firing times for this energy and time-intensive process, which in turn results in lower energy requirements. In terms of product quality, the balance is also positive: The quality is excellent.

The biggest challenge in switching to electric operation was determining the optimum process parameters for firing. In addition, the electrical infrastructure (transformer station) had to be expanded and a cooling system had to be installed for the two furnaces.