FILTRATH® and FILTRATH®CAT

Vacuum-formed products

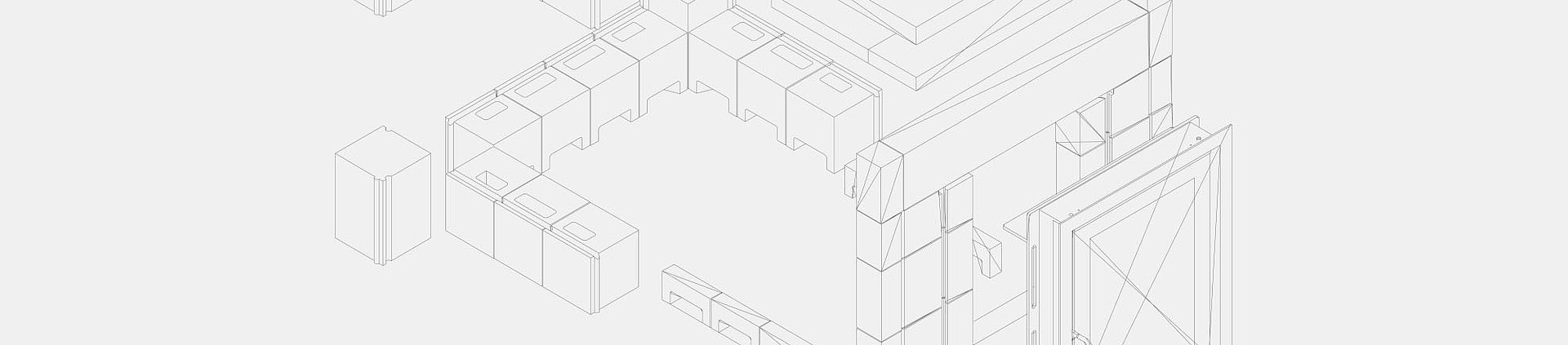

Top-class hot gas filter cartridges

FILTRATH® ceramic filter elements have been specially developed for hot gas filtration applications.

They are made of high-temperature insulating wool, are therefore very lightweight, and have a very favorable differential pressure behavior thanks to their high porosity. Their excellent separation performance meets the most stringent emission requirements.

The advantages

- high temperature-resistant

- 100 % spark-resistant

- lightweight

- robust

- highly efficient

- emission values < 1 mg/Nm³

- harmless to health (AES variant)

FILTRATH® ASW Base material: Aluminum silicate wool Chemical analysis: SiO2 60-65% w/w Max. application temperature*: 1.000 °C | FILTRATH® AES Base material: Calcium/magnesium silicate wool Chemical analysis: SiO2 73-78% w/w Max. application temperature*: 1,000 °C |

FILTRATH®

- Production and recovery of powdered substances (e.g.molten glass and metal)

- Clinker cooling in the cement industry

- Manufacture of plastics

- Waste incineration plants

- Pyrolysis and gasification processes

- Power plant processes and combustion plants

FILTRATH®CAT

Constant technological developments of sorbent and reducing agent injections combined with the length extensions of FILTRATH®CAT elements result in multifunctional solution combinations: “3-in-1” pollutant mixtures (DeDust, DeSOx, DeNOx) can be controlled in a highly effective manner with a single system. We provide you with the solution you need and are always available to advise you.

For you, this means fewer interfaces, reduction in the total plant area, and thus significant CAPEX and OPEX savings.

Advantages of dry particle separation at high temperatures:

- Economic advantages by preservation of process heat for further process steps

- Maintenance of process gas and dust properties through stable temperature control and dry particle separation

- Cost-efficient protection of catalysts

- Avoidance of corrosion and deposits in the downstream systems

- Maximum environmental protection: no use of water and hence no wastewater problems

- Compact filter design

Compliance, protection, recovery

- They ensure compliance with the most exacting emission regulations (e.g. EU-IED, EU-WID).

- They improve system efficiency and durability by protecting downstream equipment (e.g. heat exchangers, turbines).

- They prevent valuable process waste materials from entering the flue gas stream and thus enable their recovery (e.g. catalysts)