FOR THE PETROCHEMICAL INDUSTRY

MATURE REFRACTORY SOLUTIONSCRACKERS & REFORMERS

For several decades, RATH has been a partner to the petrochemical industry when it comes to reformers and crackers. Not only high temperatures but also aggressive and reducing atmospheres, as well as mechanical wear characterize the refractory challenges in the petrochemical industry.

Your benefits:

- High Quality: With our in-house production we offer you the highest possible quality refractory materials produced by RATH

- Effective: Our refractories are designed to withstand the toughest conditions

- Worldwide: Project management and consulting expertise

ABOUT

Equipment used in the petrochemical industry primarily requires good refractory insulation, even where no direct contact with chemically aggressive substances exists.

PRODUCT PORTFOLIO

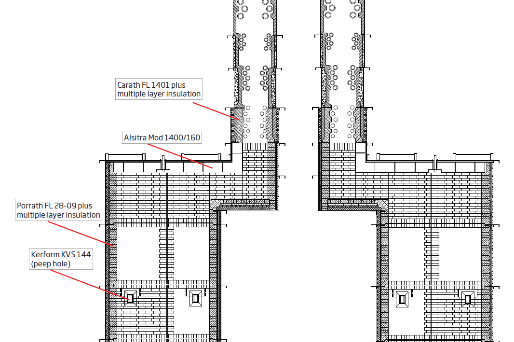

RATH provides a wide product portfolio of insulating materials including ALSITRA & ALTRA mats and modules, CARATH insulating castables, PORRATH insulation fire bricks and Kerform vacuum-formed boards and shapes to ensure insulation at every temperature i.e. for crackers, reformers, combustion chambers, etc.

IN-HOUSE MANUFACTURING AT THE HIGHEST QUALITY

The petrochemical industry, but also the servicing OEMs appreciate the fact that RATH manufactures all the refractory products required to insulate these units in-house.

RADIATION ZONE

Depending on temperature, gas velocity, flame impingement and ambient requirements, as well as expected maintenance-free operation, we select the lining for the radiation zone. Porrath insulation fire bricks and Alsitra mats and modules provide the required insulation.

CONVECTION ZONE

Typically, the convection zone is lined with Carath insulating castables. The convection zone is divided into temperature segments that each utilize a multiple-layer system targeting optimum insulation and hence the lowest possible energy loss.