GLASS MELTING CRUCIBLES FOR HANDMADE GLASS

RATH has been developing and manufacturing high-quality refractories for more than 130 years. For the past 50 years, RATH has specialized in the production of glass pot refractories and provided the art glass industry with high-quality glass melting crucibles.

The products are manufactured in various grades of clay flux, fortified mullite, zircon-mullite, AZS, and fused-silica formulas, and the pots are supplied either green or fired, depending on customer requirements.

YOUR ADVANTAGES

• Different refractory compositions for different glass qualities and applications

• Durability and long life

• Round bottom or straight wall designs

• Standard and custom shapes

• Excellent thermal shock resistance

• Excellent corrosion resistance

• Green and fired pots

• Crucibles, pots, day tanks

Energy saving

Longer service life and better glass quality thanks to our fired crucibles with significantly shorter heat-up time!

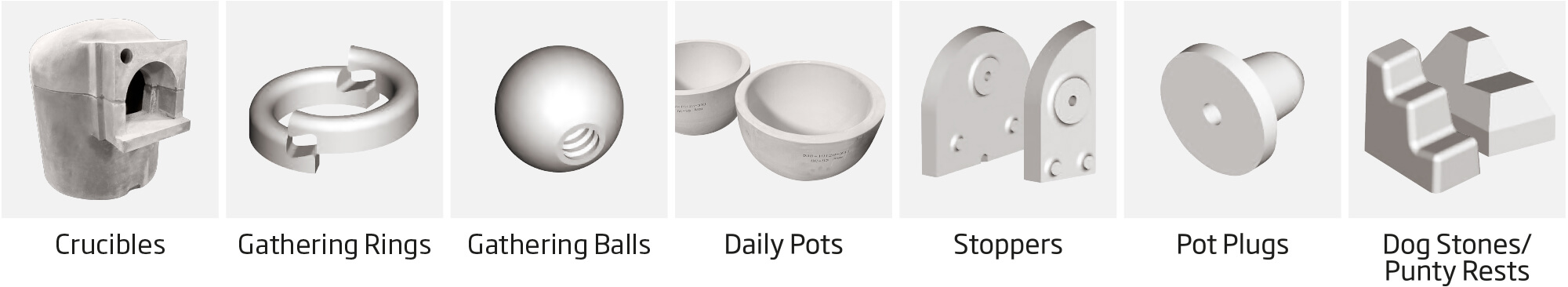

WE SUPPLY

• Glass melting crucibles from 1.5 kg/3 lbs up to 2000 kg/4400 lbs effective glass weight

• Crucibles according to customers’ individual design

• Day tank refractories

• Rings and half rings

• Gathering balls

• Stoppers

• Dog stones, pot plugs

• Clay, luting cements, mortars and monolithics

• Insulating bricks, blankets, felts and boards

Downloads

In a NutshellTHINK HIGHER

RATH understands that the basis for superior glass conditioning in all areas of the glass industry is high-quality refractories. Their use in forehearth and feeder mechanisms plays a crucial role in the formation and conditioning of glass before it is formed into finished product.

OUR QUALITY PROMISE

Artisans and craftsmen prefer only the best materials. Those who want to fully develop their artistic skills rely on the best materials and tools. RATH products for the entire range of applications in art glass production are an adequate partner for the full development of all possibilities. Only the best raw materials are used and our employees manufacture the products by hand with passion, precision and dedication to detail. Each single one, just for you.

All RATH refractories are formulated from the highest quality raw materials and designed to achieve predictable density and resistance to erosion and corrosion. Precise PC monitoring of batching and kiln firing ensure the highest quality performance and durability.

PRODUCTS DESIGNED FOR YOU

RATH glass melting crucibles have proven strength, durability and wear resistance to provide maximum furnace uptime.

RATH offers crucibles in a wide range of compositions, sizes, and shapes, such as:

OPTIMAL PERFORMANCE

All of the refractories are designed to deliver optimal performance. Materials and processes are controlled to achieve consistent high performance. The staff are a team of professionals committed to reducing your costs through effective use of the product line.

RATH’s commitment to your success can be seen in our laboratory and plant facilities where people, processes and products are brought together to meet the needs of the customer. We have extensive in-house capabilities for raw material testing, process control and product development. This is complemented by external technical support from University of Missouri facilities.