Heat treatment and steel processing competence

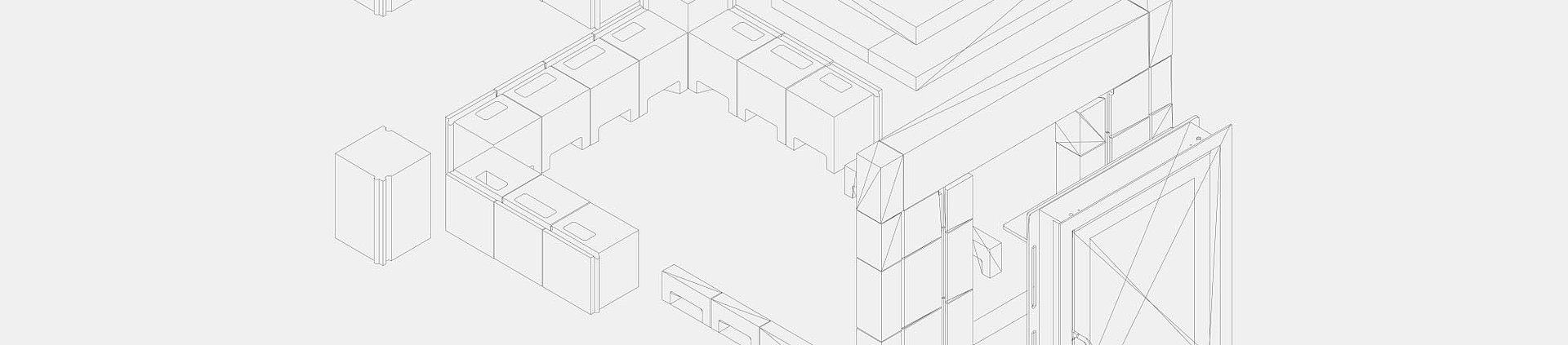

Provision of a solid refractory lining does not start with ordering material and does not end with delivery of the material to the plant manufacturer or user. A complete solution includes professional selection of materials, solid construction, quality-focused delivery and efficient project management.

With expertise and years of hands-on experience, our project managers worldwide ensure the execution and coordination of refractory linings for iron and steel smelting. This means RATH customers have a reliable partner for refractory plants with a comprehensive service portfolio.

ENGINEERING

The basis of every lining concept is the heat transfer, which will determine the optimum wall structure. Extensive knowledge of thermal and corrosive loads is required. We use modern heat transfer calculation programs and software systems to calculate thermodynamic equilibriums and phase diagrams. We, as a manufacturer, have access to extensive databases, which are required for the calculations.

Upon request, we are also able to carry out economic calculations of refractory linings, taking material and energy costs into account, which provides customers with the support they need to make decisions.

MATERIAL SUPPLY

RATH material is made to order for customers and according to the agreement, with experienced shipping companies delivering directly to the construction site. No matter where in the world the construction site is, our logistics experts ensure reliable and punctual delivery.

ASSEMBLY MONITORING / SUPERVISION

RATH also handles assembly supervision in many cases with regard to assembly by third-party companies so that the construction is guaranteed according to RATH'S strict quality requirements.

ASSEMBLY

Refractory linings of liquid steel plants require expert on-site assembly. Our highly trained assembly staff ensure reliable installation and attach great importance to high safety standards. This includes continuous monitoring of construction sites by experienced installation directors.

We attach great importance to high quality assembly equipment and assembly aids to ensure effective and quality delivery.

MAINTENANCE AND REPAIR

We monitor the performance of your refractory lining and provide the necessary maintenance to ensure safe operation of the equipment.

We also offer ongoing predictive maintenance and repair.