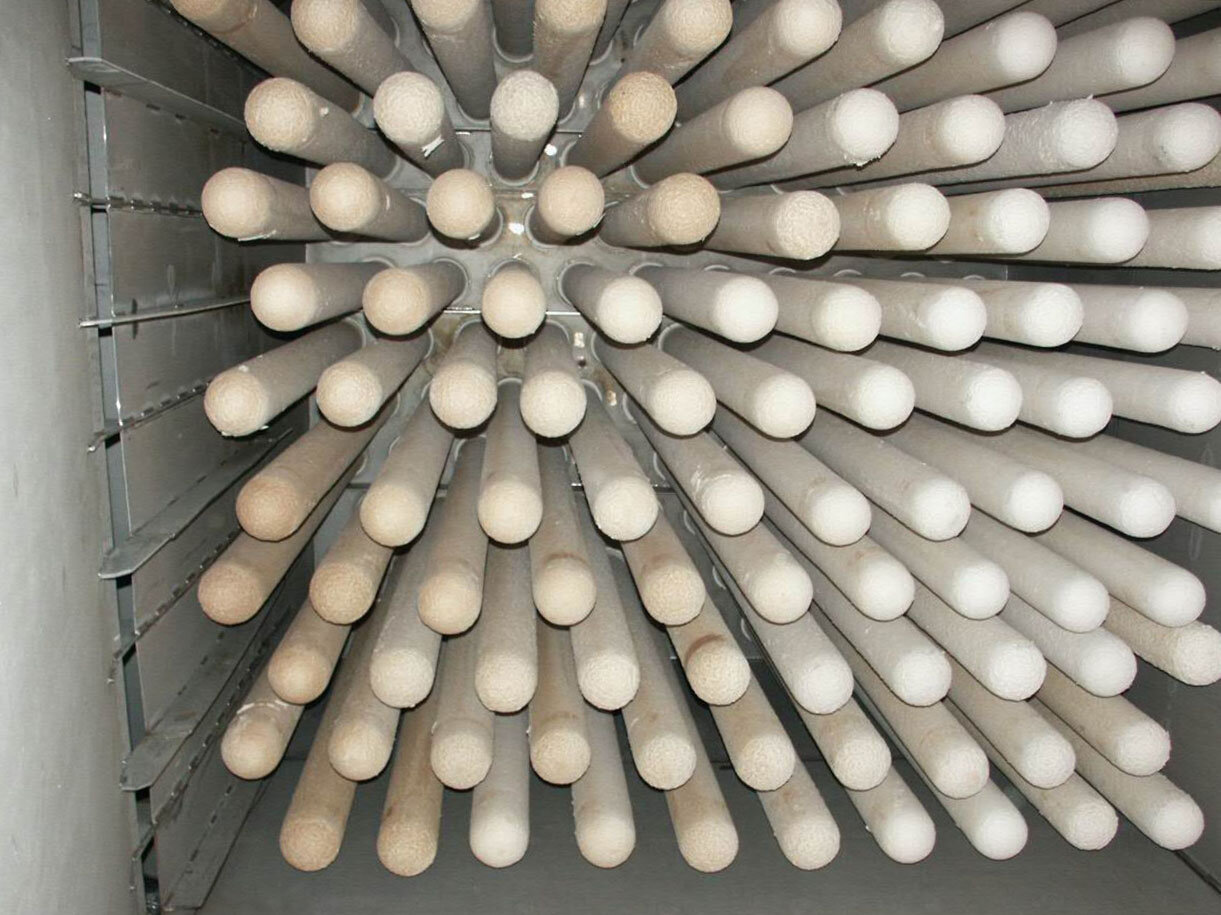

Flue gas filtering

FILTRATH® AND FILTRATH®CAT

PARTICLE AND PARTICULATE MATTER CONTROL (DEDUST)

The FILTRATH® filter elements are part of the flue gas control system and are used in conjunction with a so-called reverse pulse air purification system. FILTRATH® filter elements are highly effective in controlling PG emissions (<2 mg / Nm³) for hot gas temperature applications in the range from 250 to 1,000 °C. Thus, far above the maximum operating range of textile filters and far below the achievable emission values for non-blocking filters.

ACID GAS (SO2, HCL, HF) AND PARTICULATE CONTROL (DESOX, DEDUST)

In combination with dry sorbent injection (DSI) (e.g. sodium bicarbonate, lime hydrate), FILTRATH® elements enable effective control (> 98%) of the acid gas components (e.g. SO2, HCL, HF) and particulate matter.

With upstream injection of powdered activated carbon (PAC), FILTRATH® filter elements are also very effective in removing heavy metals such as mercury.

NITROGEN OXIDE (NO, NO2) AND PARTICULATE CONTROL (DENOX, DEDUST)

Performance can be further improved by introduction of an SCR-coated filter element, FILTRATH®CAT. In combination with upstream injection of an ammonia-based reducing agent (e.g. aqueous ammonia, urea), FILTRATH®CAT enables highly effective control (> 95%) of NOx emissions and fine dust at temperatures up to 420 °C.

When operating above the de novo synthesis temperature, FILTRATH®CAT elements also control the emissions of dioxins and furans (PCDD/F).

POLLUTANT MIXTURE CONTROL (DEDUST, DESOX, DENOX)

The combination of DSI and SCR (Selective Catalytic Reduction) processes with hot gas filter cartridge technology permits dedusting, desulfurization and denitrification of flue gases within one system.