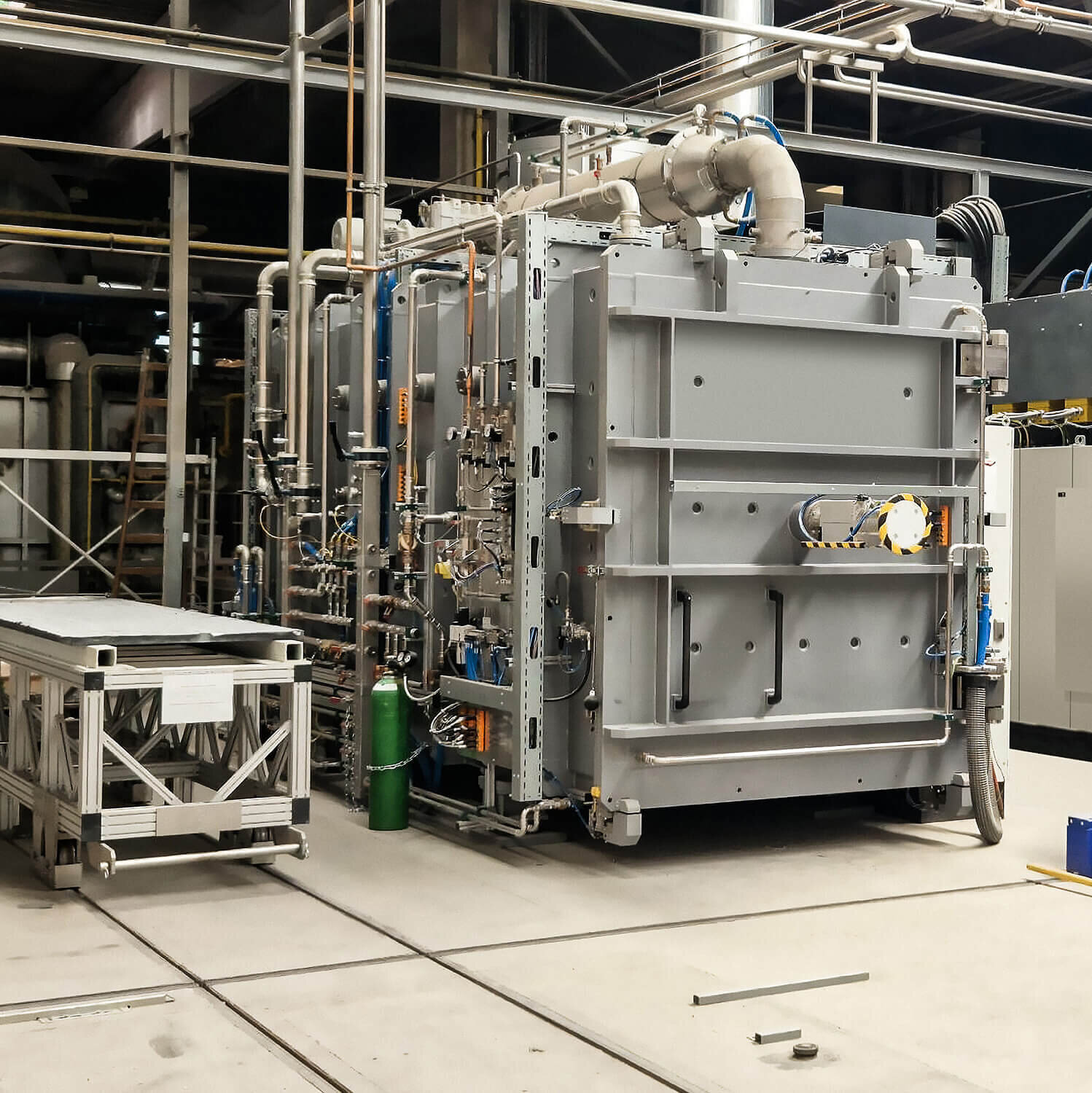

Rath Converts Vacuum Nitriding Furnaces to Electric Operation

By changing the heat-treatment process from gas to electricity, the existing material and geometry of the firing boxes were adapted and integrated into the firing chamber. To enable the products inside the boxes to be exposed to a nitrogen atmosphere, the firing boxes have to be subjected to high temperatures. The aforementioned changes allow for shorter heating and firing times for this energy- and time-intensive process, which in turn results in lower energy requirements.

“We carried out trials in small batches in collaboration with the furnace manufacturer. The furnaces were ordered after numerous tests had been carried out in external laboratories and had yielded optimum quality. The procedure has paid off. The product quality is outstanding,” said Heinz Wallner, head of production at the Krummnussbaum plant.