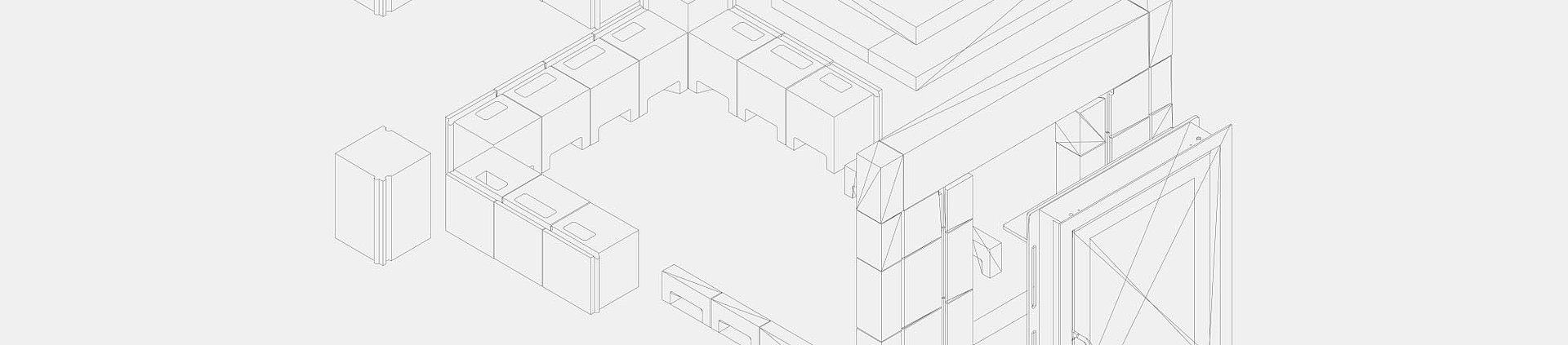

Carbon black reactor

Tread reactor for hard carbon black In a tread reactor, extreme temperatures above 1900°C prevail. Reducing atmospheres, water quenching processes and gas velocities in the supersonic range require maximum performance and quality in terms of mullite and corundum bricks, as well as precision concretes. Tread reactors require precisely shaped bricks to withstand high gas velocities and pressure differences. RATH choke systems are based on polished bricks, which fit perfectly together, thereby ensuring a long service life. RATH carbon black chokes are made of corundum bricks and chrome corundum bricks. Carcass reactor for soft carbon black. The carcass reactor is used to create soft carbon black. These horizontal or vertical reactors are operated at slightly lower temperatures than tread reactors. The challenge lies in the size and mode of operation of the systems, or the high amounts of alkali additives that are often used. The temperatures often do not exceed the 1600°C limit and therefore allow lining with mullitic bound corundum bricks.