RATH: Successful refractory lining for hearth-type melting furnaces

Such a solution has now also been developed for the relining of a hearth-type melting furnace in the aluminum smelter of Aluminium GmbH Nachrodt (AGN) in the Sauerland region of Germany. Removal and relining were successfully completed in just 21 days.

The requirements were demanding: The removal and relining of a tilting hearth melting furnace was to be completed as rapidly as possible during the 2022 Christmas holidays and turn of the year. An additional major challenge of the project: The burner technology in the top furnace was simultaneously rebuilt with major interventions in the steel structure of the furnace.

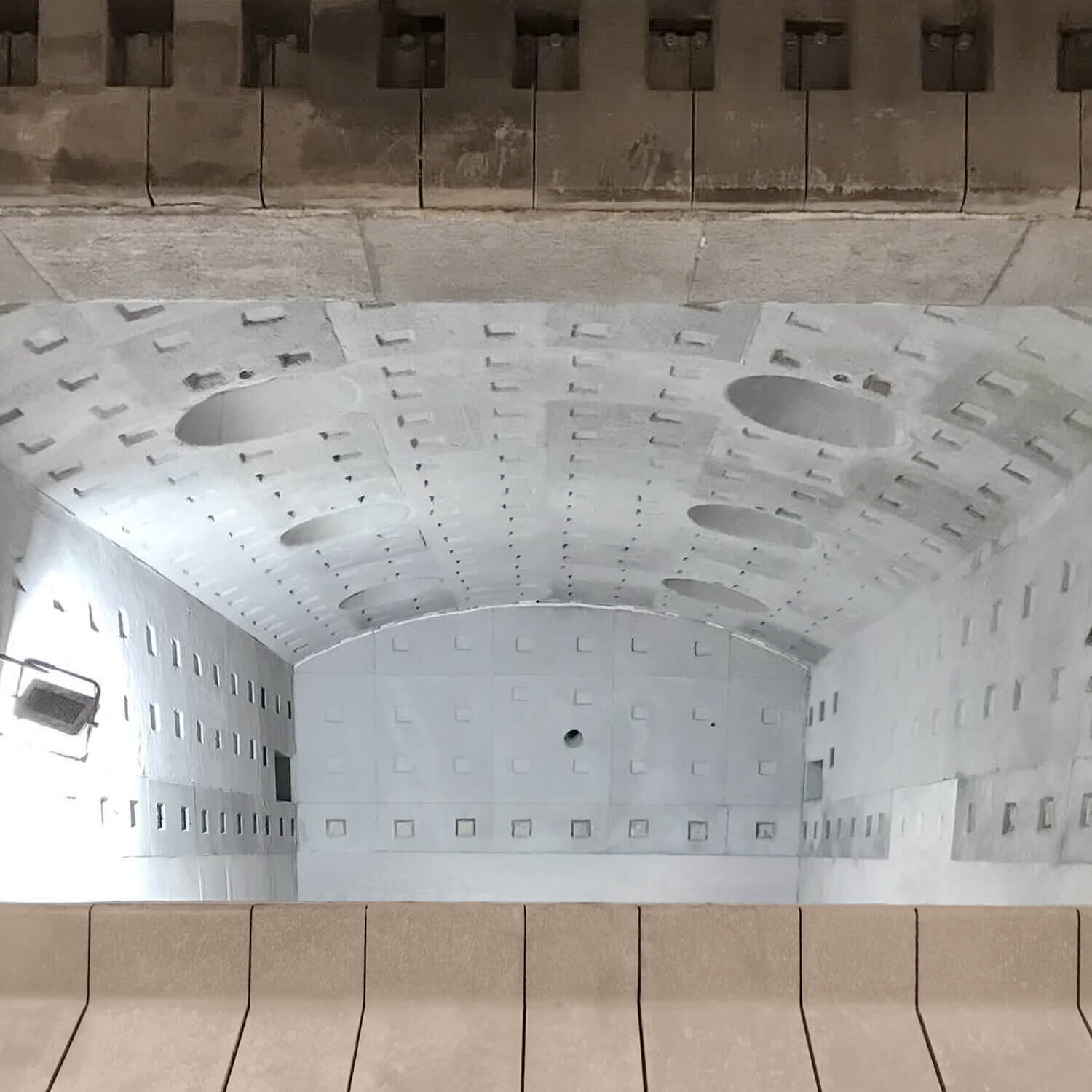

Mission accomplished: The specialists of the internationally active refractory manufacturer succeeded in carrying out the technically demanding lining in only three weeks. 75m3 were lined with a total of 115 tons of refractory material – 17 tons of which in the form of precast concrete components weighing between 230 and 530 kilograms. The floor, ramp, bridge and lower side wall were lined with the proven component concept. Furthermore, Nachrodt relied on RATH's experts when it came to heating: The plant was heated externally with built-in steam pressure and temperature sensors in the refractory lining of the bath.