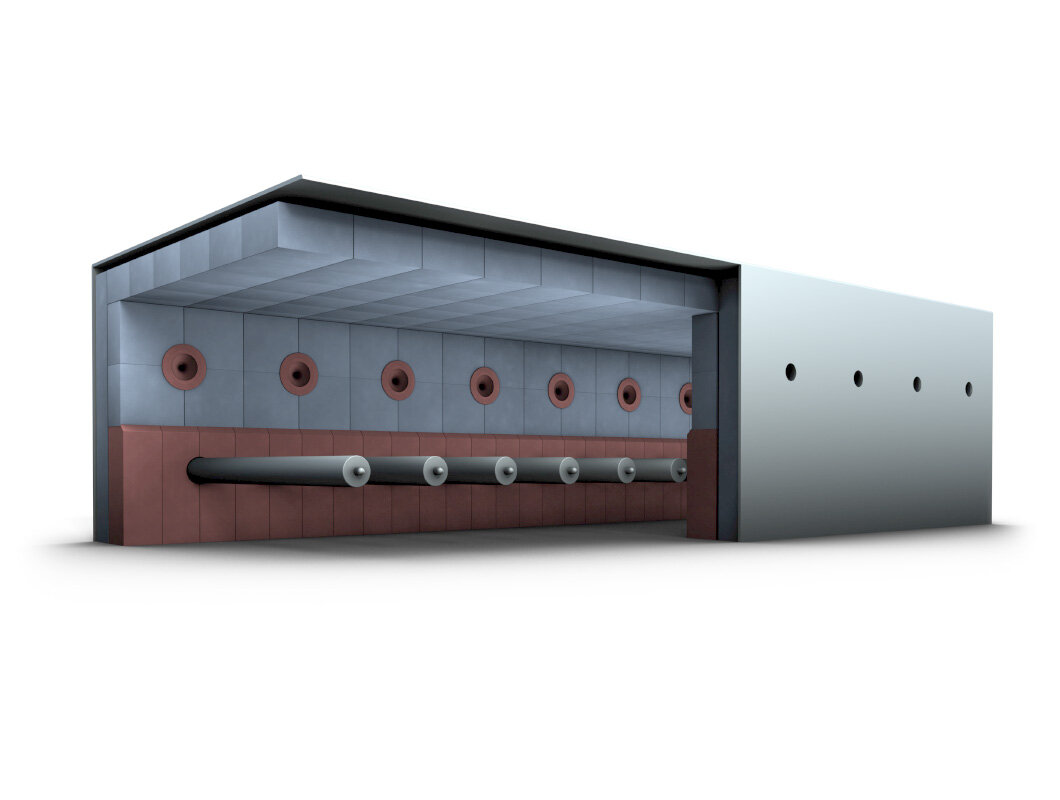

Roller furnace

The roller furnace, a type of continuous furnace, is primarily used to heat slabs or strips in a continuous production process at temperatures up to 1150°C. The heat treatment can be carried out with or without protective gas.

The combination of precast concrete parts and vacuum formed shapes in the roller area ensures mechanical resistance in the kiln chamber on the one hand, and on the other, a perfect seal of the roller passage. Depending on the requirements, we use dry-pressed bricks or insulating fire bricks for the area under the kiln, and products made of high-temperature insulation wools are used above the roller area. The mix guarantees an optimal energy balance.